INTRODUCING Eagle SmartTrac IoT MACHINE TECHNOLOGY

Advancing manufacturing solutions with Industry 4.0 Technologies

Optimize Your Automation Asset Today

Reduce rework

Increase asset uptime

Reduce maintenance time

Increase production associate productivity

TODAY’S SOLUTION FOR TOMORROW’S MANUFACTURING

Eagle’s SmartTrac solution provides a forward-thinking approach to solving your manufacturing headaches. Featuring:

- Machine Notifications

- Production Management

- Process Control

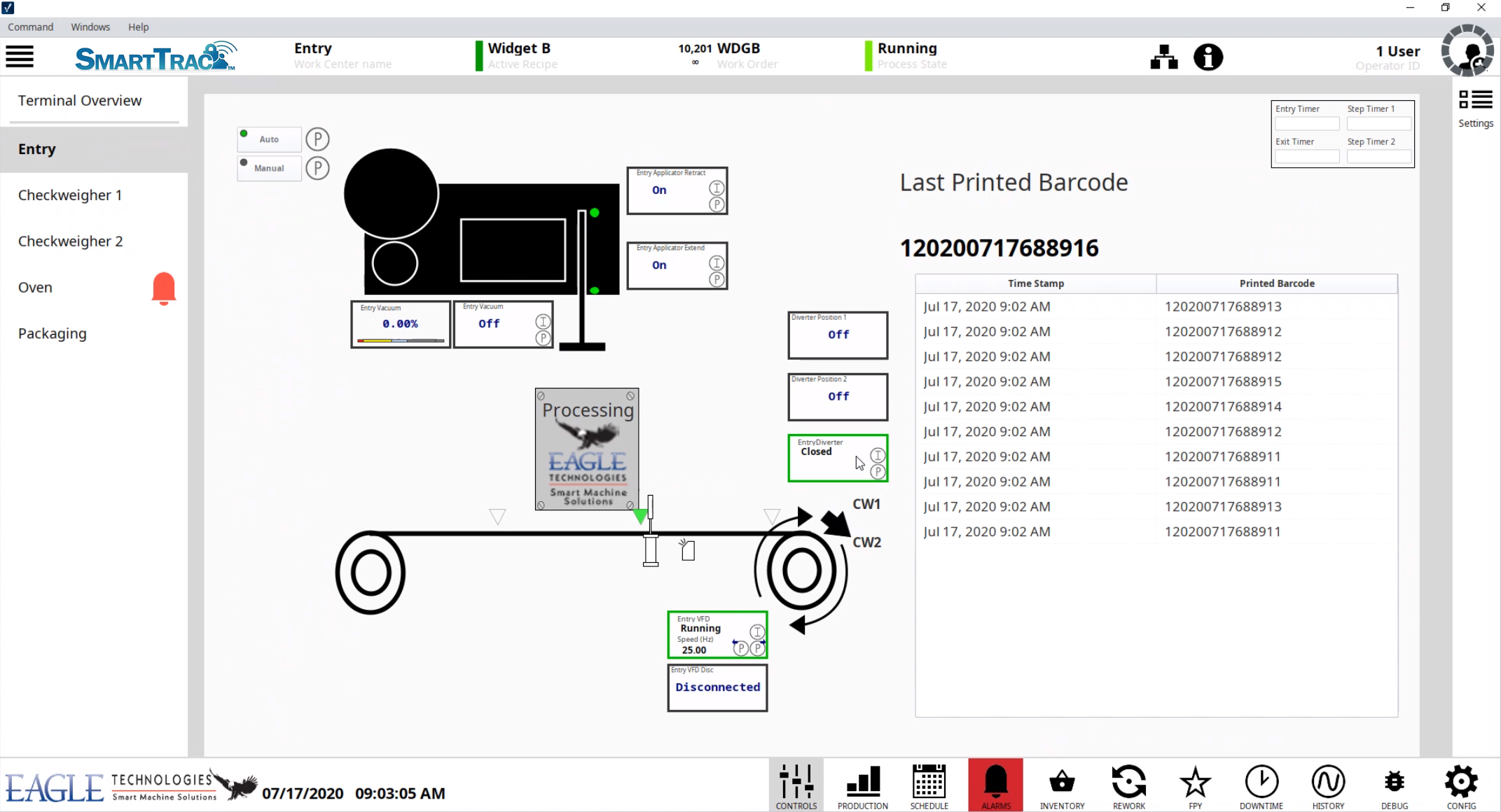

- Traceability

- OEE & Downtime Tracking

- Big Data Analytics

- KPI Dashboards and Reporting

- Augmented Reality

WHAT IS SmartTrac?

Eagle SmartTrac is an industrial enterprise software that leverages IoT hardware devices we integrate and deploy into our automation systems. We integrate SmartTrac software to improve asset management, decision making, and operational visibility for our customers and internal Eagle value stream contacts such as service, support, and spare parts. Our solution emphasizes uptime and minimizing production loss through sophisticated and segmented network designs. Working with our customers, Eagle engineers layout a design that will reduce cost drivers in every automation asset we design and build. Streamlining and optimizing your automation asset to reduce unplanned downtime.

PLATFORM HIGHTLIGHTS

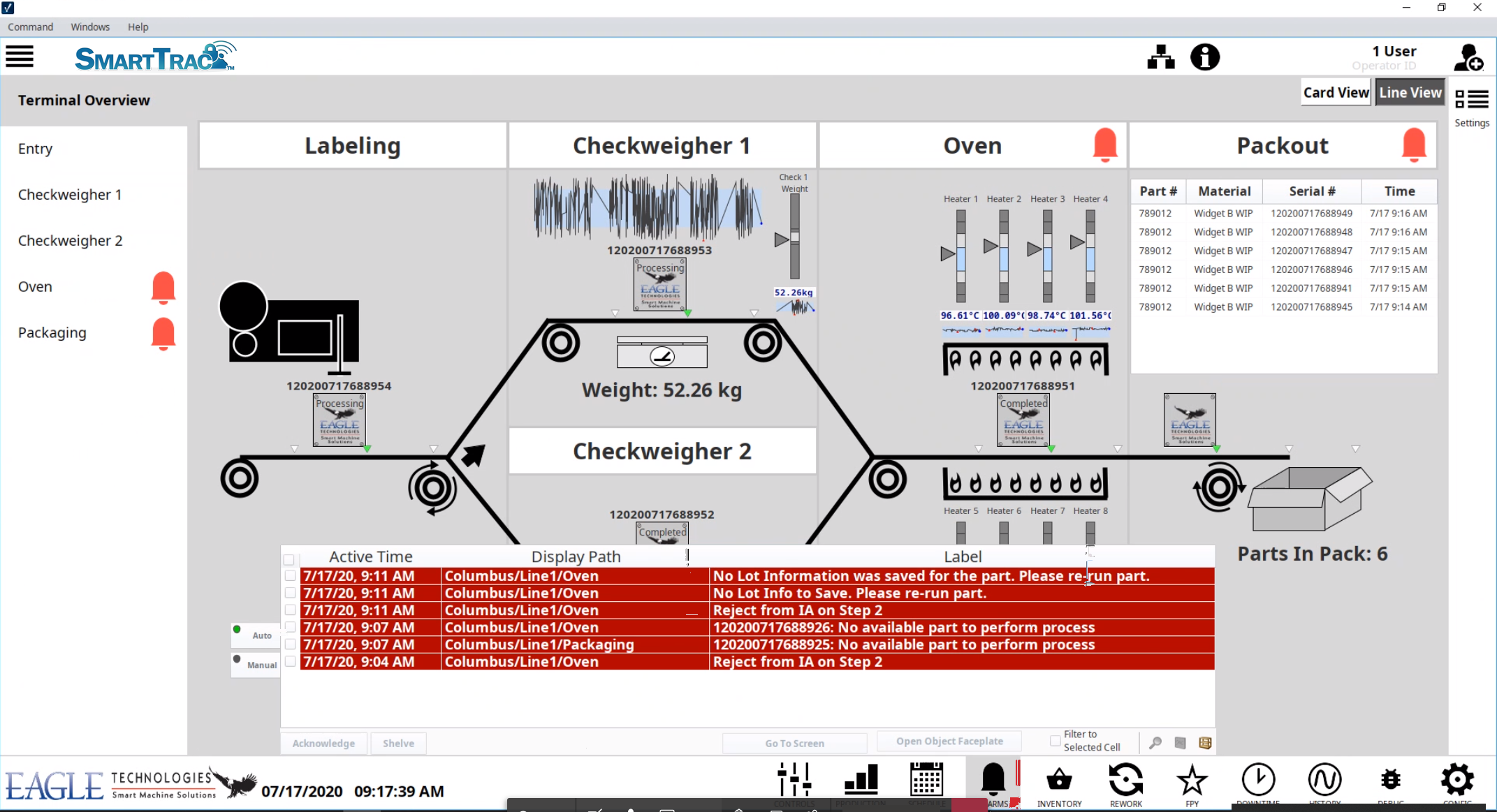

Eagle SmartTrac utilizes Industry 4.0 Technologies to improve insights and actions across automation assets of our customer’s factory. We gather complex machine data from networked devices like I/O blocks, torque drivers, vision cameras. Our IIoT software platform SmartTrac monitors IoT endpoint devices and event streams (I/O, Variable feedback, Error recovery) which give our customer insights into every machine process. SmartTrac is your gateway to managing your production, from downtime notifications to production management, SmartTrac is available in various levels to accommodate many different needs.

NOTIFICATIONS

The only thing better than a machine that never goes down is one that gives you plenty of advance notice. That’s what the Eagle’s SmartTrac is designed to do. It not only delivers on-screen fault notifications to your operators, but it is also proactive in identifying maintenance concerns early so that your team can schedule maintenance during planned downtime, instead of having to conduct emergency repairs during peak operating hours.

The SmartTrac software can be configured to send alerts via HMI messages, emails, and text to anyone our clients choose. Whether you want to alert the floor manager, on-duty staff, or even a contact at Eagle so that we can prepare a spare tooling quote and have your replacement part ready as soon as you need it.

Monitoring and notifications are also available for life cycles of perishable tooling and critical preventative maintenance items.

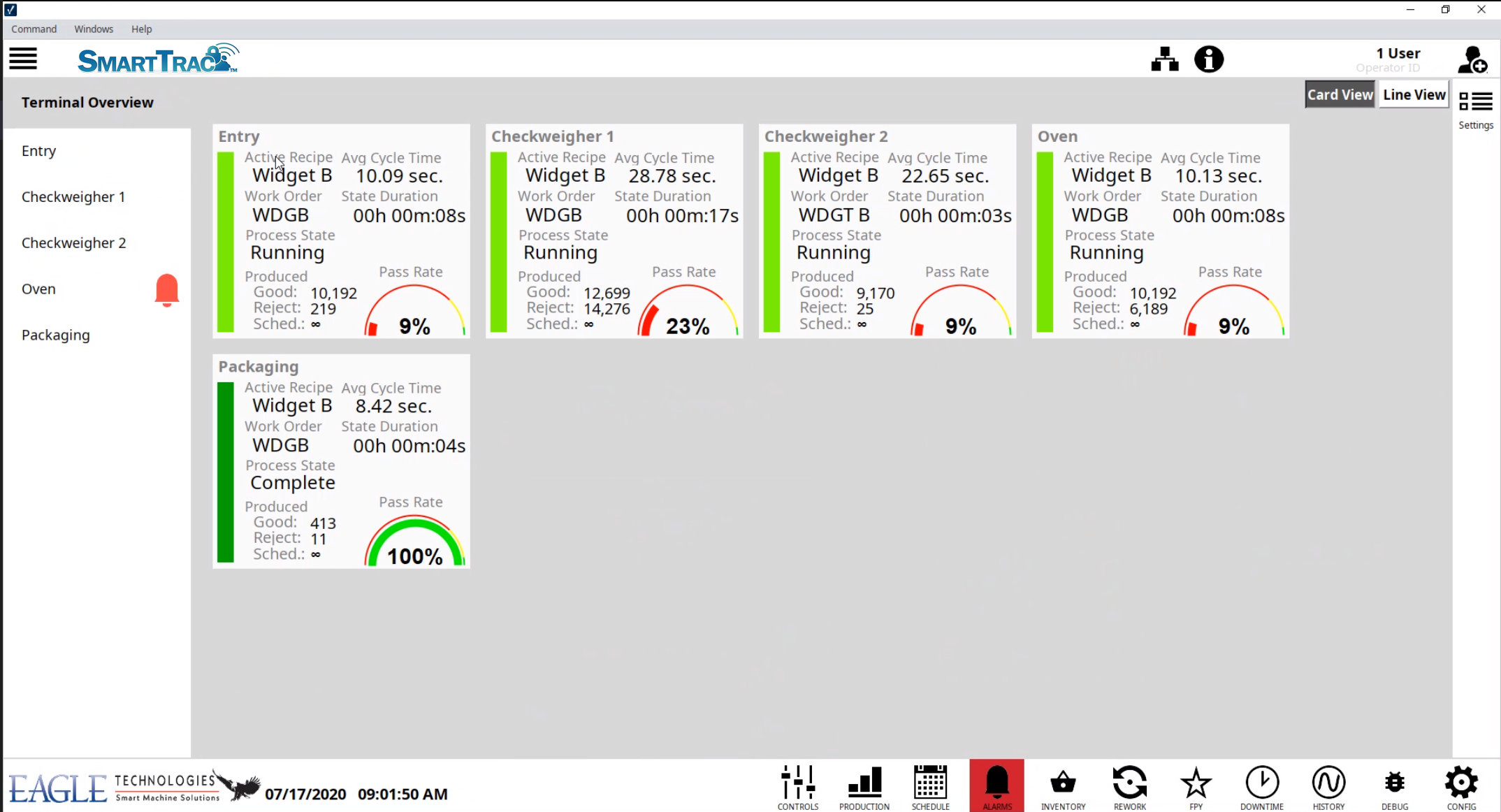

PRODUCTION MANAGEMENT

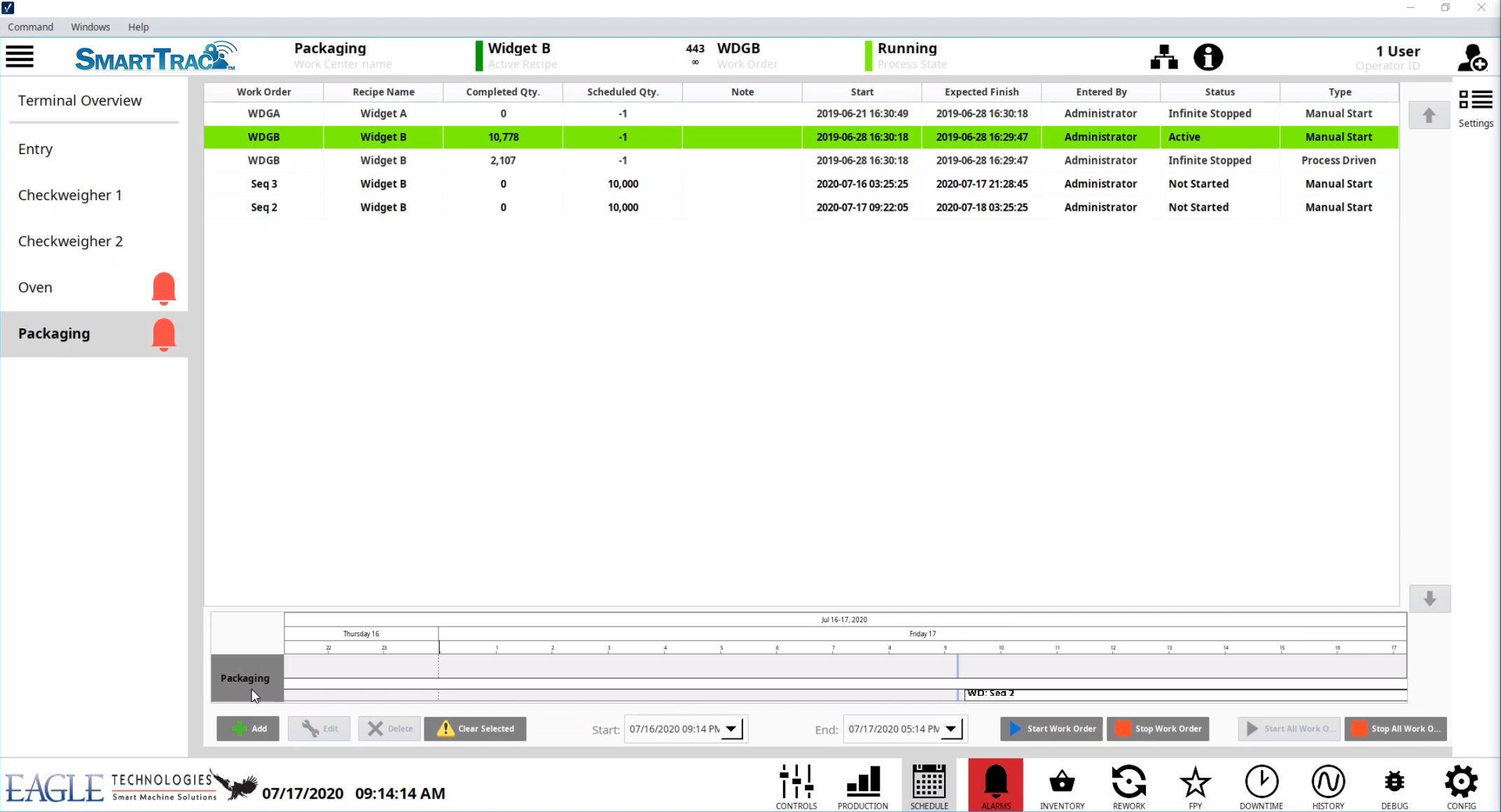

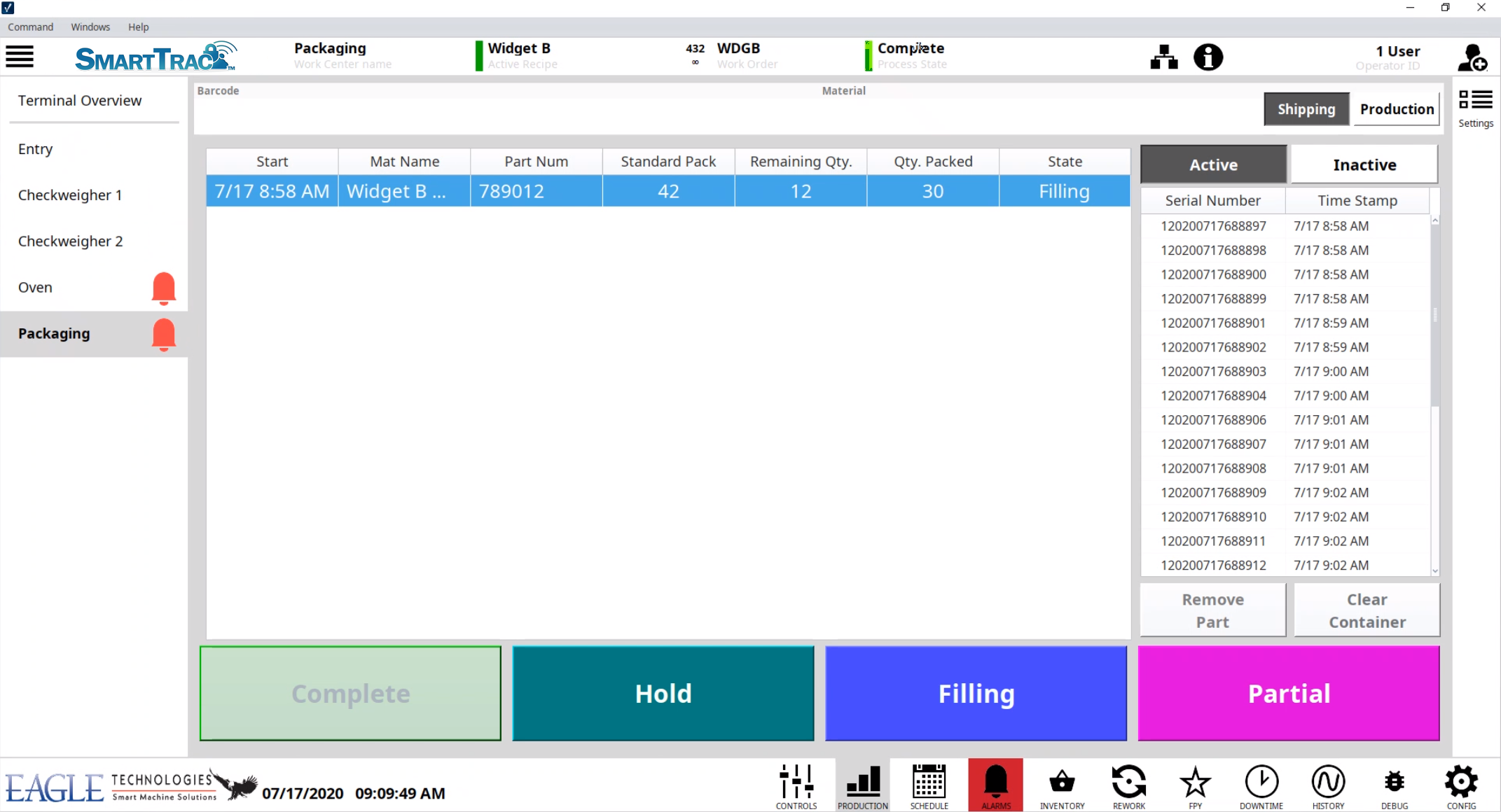

The new SmartTrac puts manufacturers in full control of their production process management. Whether you want to control production manually, schedule production to run at certain times, or have it begin automatically based on the status of other steps in the production process.

In the meantime, our system enables high-level oversight of the entire production line. Track production progress in real-time for a perfectly up-to-date look at your factory operations, or create an overview of factory performance during a specific time period. And, because our devices can share data with any of your production consoles, you can keep your entire team in the loop.

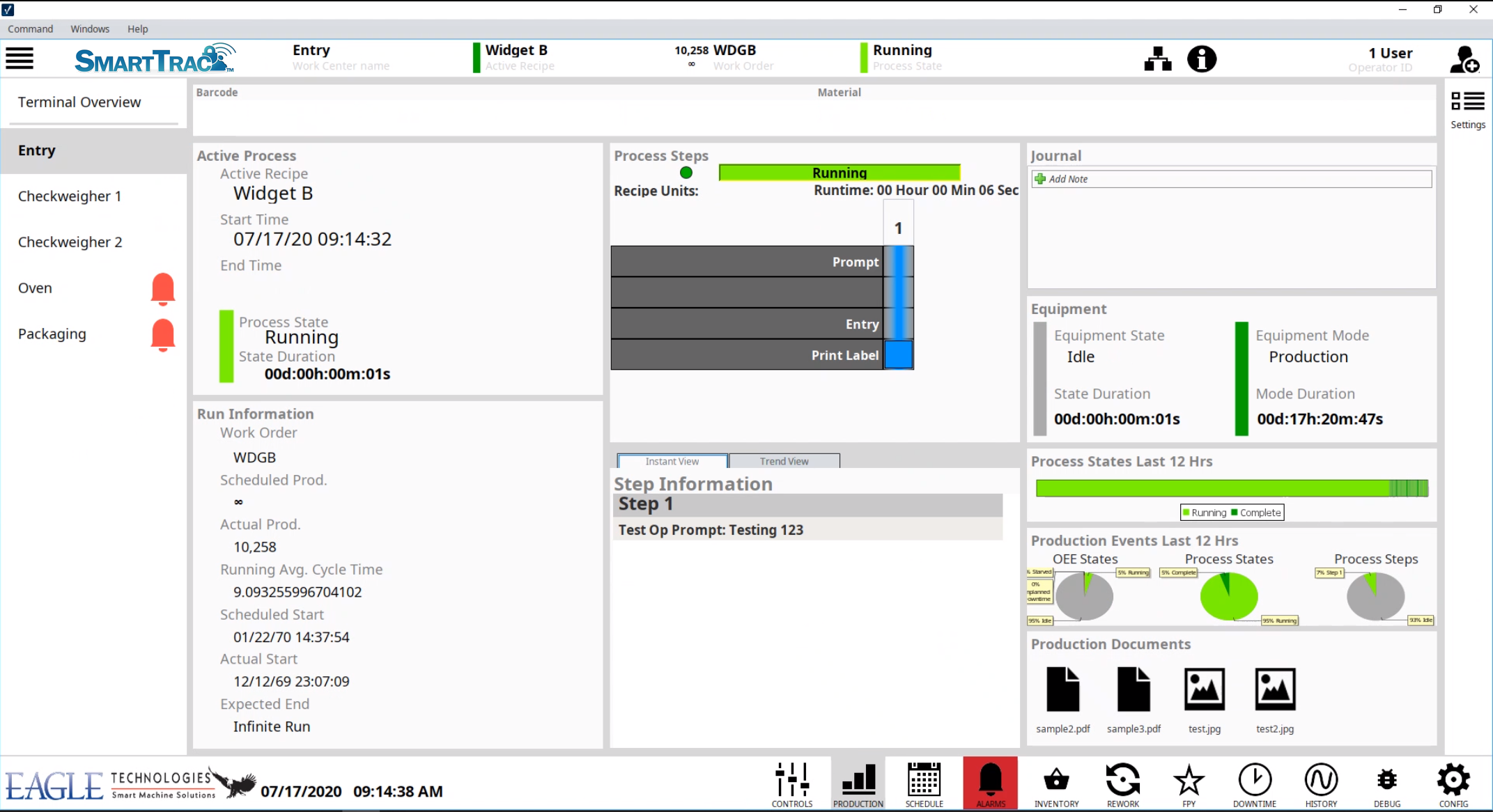

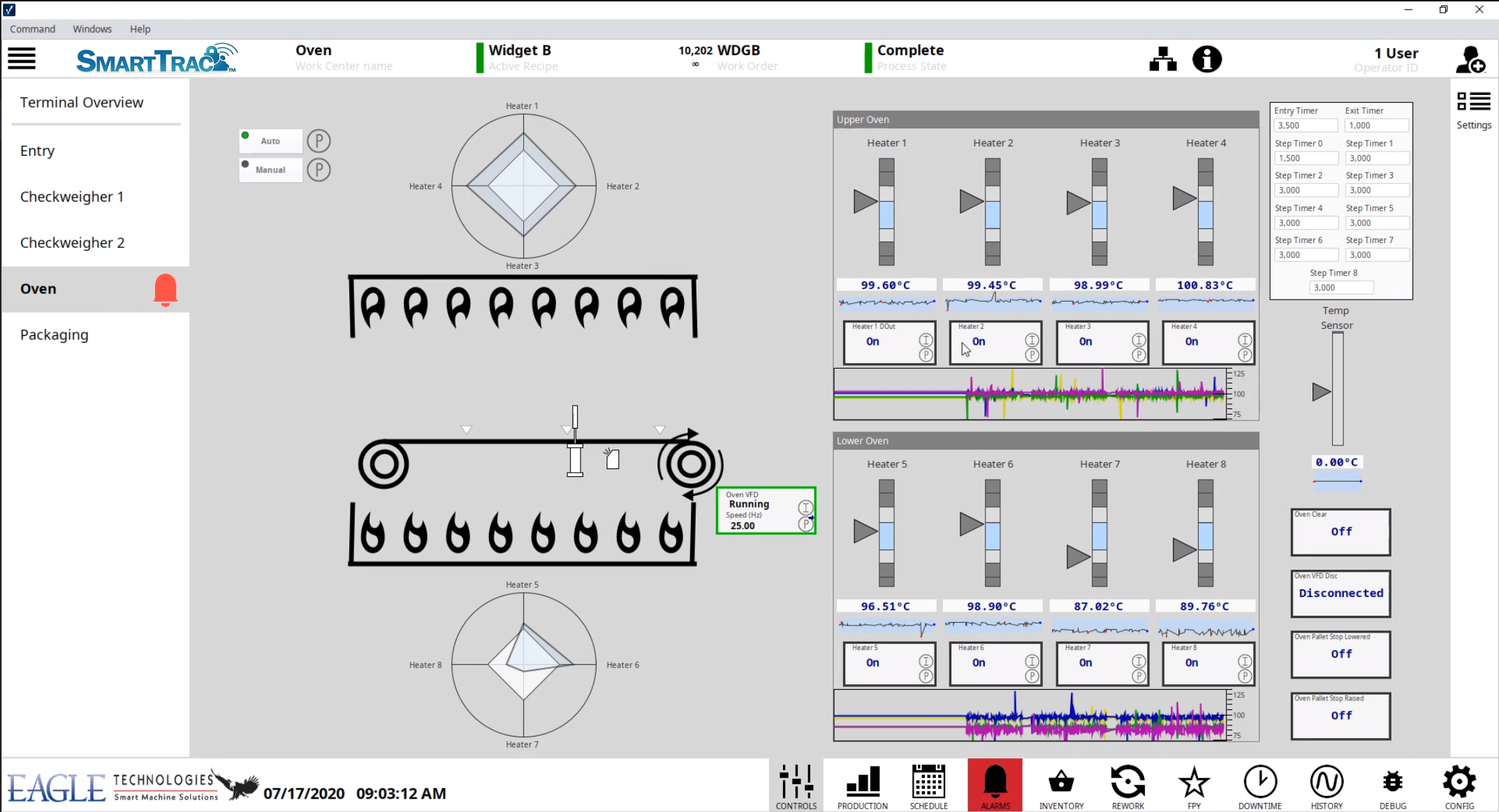

PROCESS CONTROL

Want to adjust the pass/fail tolerances for quality control purposes? Deliver specific workflow responses to operators that are triggered by certain production conditions? Allow your operators to leave shift notes for their coworkers?

The Eagle’s SmartTrac solution not only informs you of the status of your current manufacturing operations, but it also helps you direct how your operators respond in various situations. By improving communication and coordination among your factory workers, you can reduce production errors and improve overall operational efficiency.

Eagle’s SmartTrac solution provides access to several key pieces of the puzzle:

- Monitoring of parameters to ensure they are in-tolerance

- Visualization of active process steps and real-time pass/fail status

- Recipe drive operator instructions available at the operation

- Ability to enter shift notes for other operators and maintenance

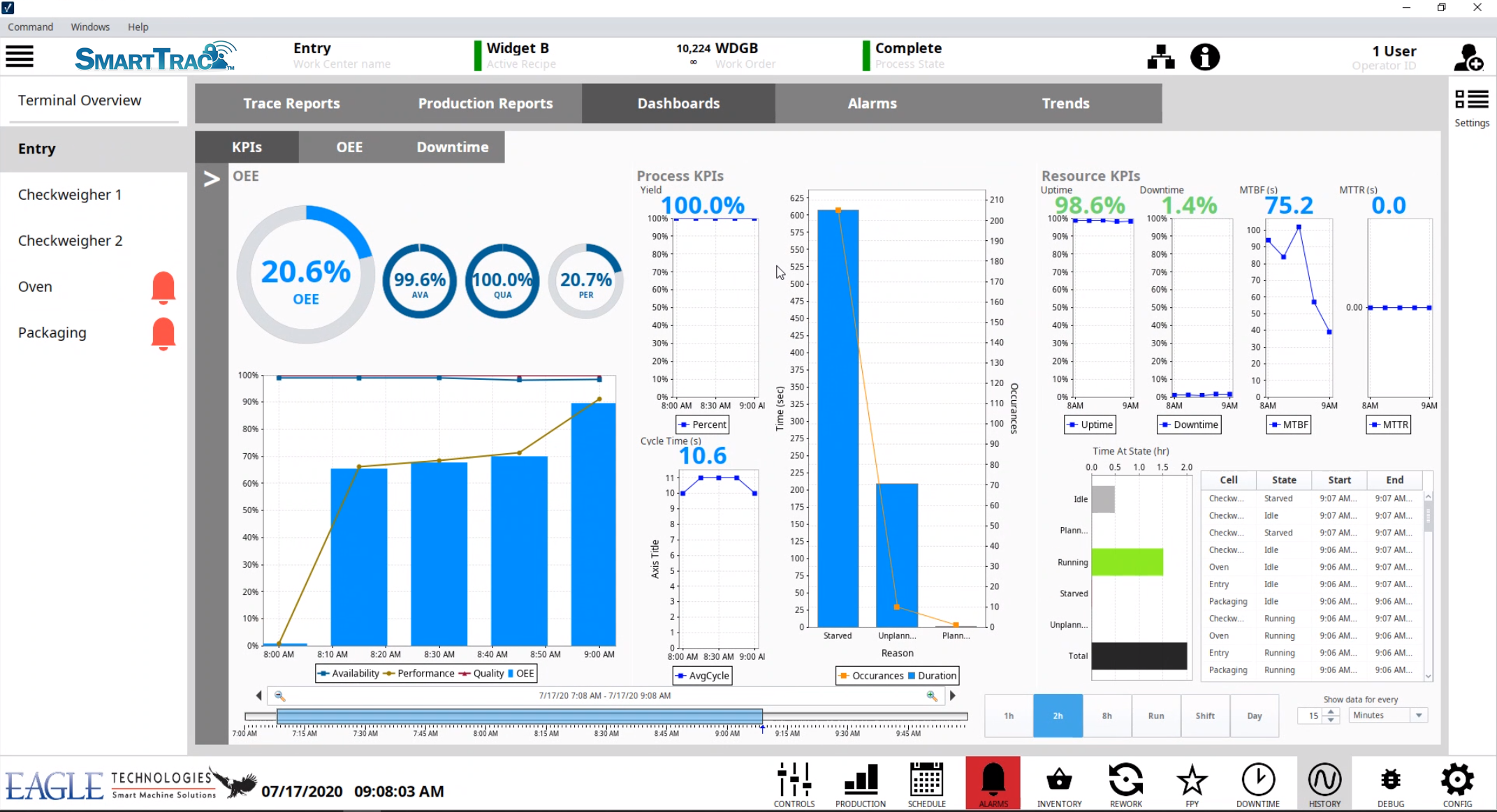

OEE

Achieving ideal operational effectiveness isn’t just about monitoring components, it’s also about optimizing the equipment that produces them. A machine that is underperforming or contributing to production errors can slow down an entire factory. When this happens, it is essential for manufacturers to have the information at hand to quickly identify and address the problem.

The Eagle’s SmartTrac OEE module tracks detailed information about each machine and station, from its maintenance history to downtime statistics to operator use. Know how your equipment is being used so you can improve performance.

Eagle’s SmartTrac is configurable for operator use and offers the ability to capture downtime related to the equipment for the OEE calculation. Downtime events can be revised, split into multiple events, and allows operators to add notes.

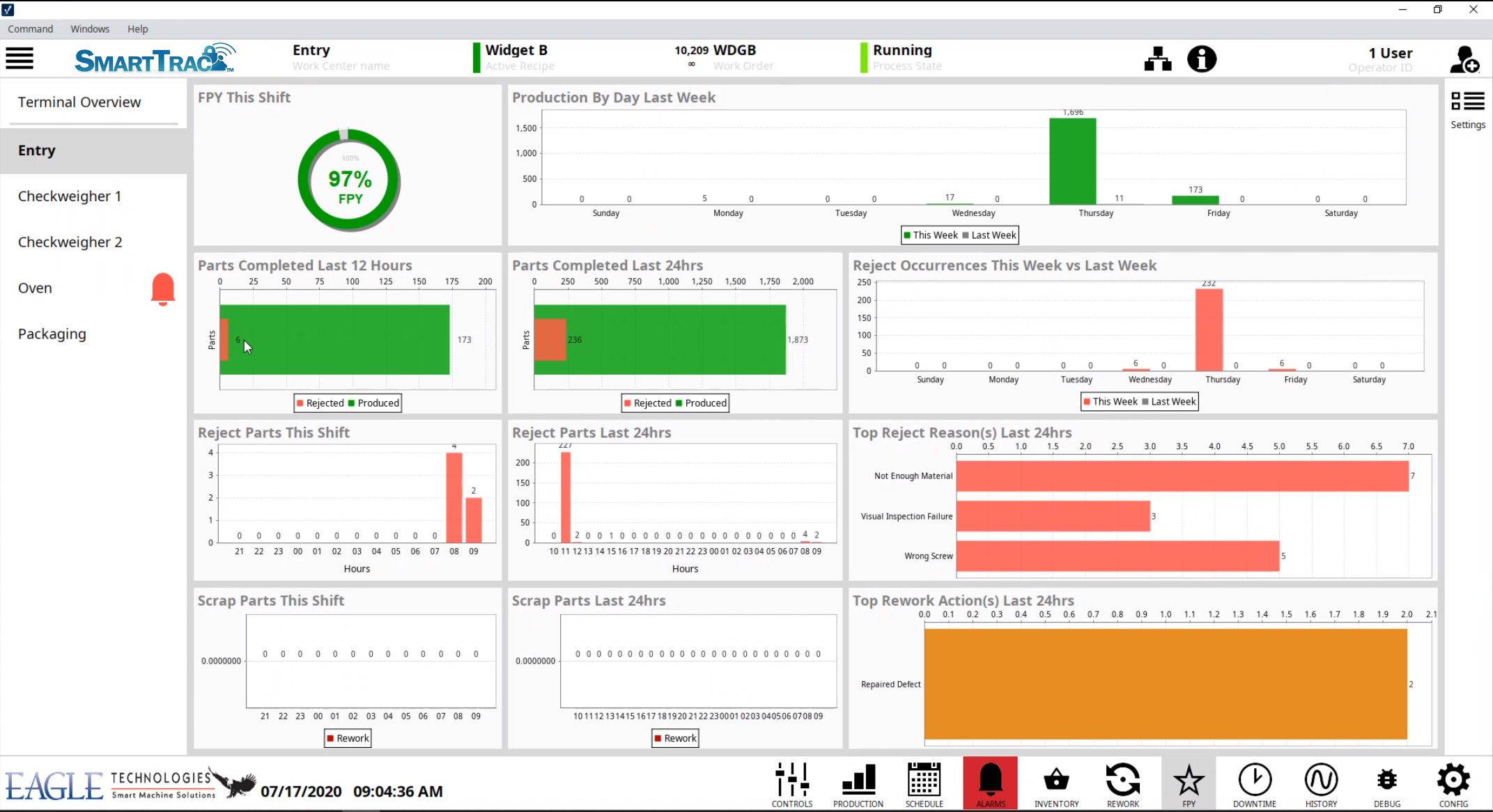

BIG DATA ANALYTICS VIA DASHBOARDS AND REPORTING

Every stage of our process offers an opportunity to collect vast stores of data that manufacturers can draw on as they analyze their production performance. This data can be put to use immediately, and also stored for future analysis. This gives you the flexibility to analyze production data in any number of ways, including ones you haven’t yet considered.

We don’t use the word “smart” to describe our machine for nothing. While in many cases “smart” devices are merely those that are WiFi-enabled, ours draws on the machine tracking capabilities to understand the data being collected, and deliver actionable insights to manufacturers.

KPI reporting and monitoring dashboards provide efficient oversight. Every company has different performance standards, special factors they want to track and monitor, and their own set of production quotas to meet. That’s why our SmartTrac technology is designed to deliver both standard and custom reporting metrics, so that your operators can monitor system progress at a glance.

By linking Industry 4.0 technologies in one interface, manufacturers will gain greater insights into their production systems and have more control over every step of the process. That’s what we call smart manufacturing.

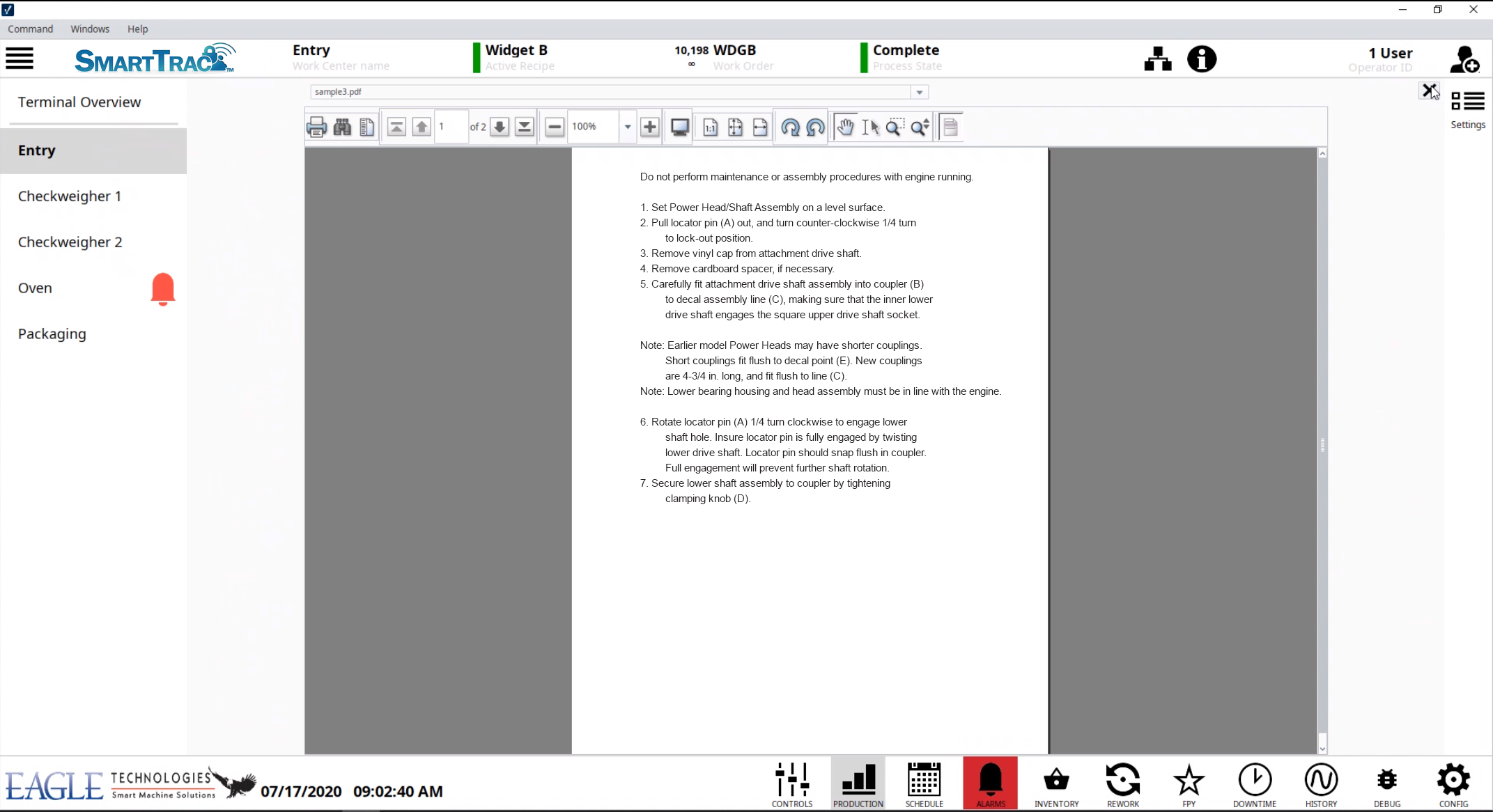

AUGMENTED REALITY

Utilizing AR technologies, SmartTrac will go beyond simple maintenance schedules, AR solutions enable you to create and deliver easily-consumable instructions and troubleshooting. Empower your technicians with real-time access to relevant information to solve problems faster and reduce service costs. Our integration of Vuforia into our customer’s automation improves uptime and saves costs.

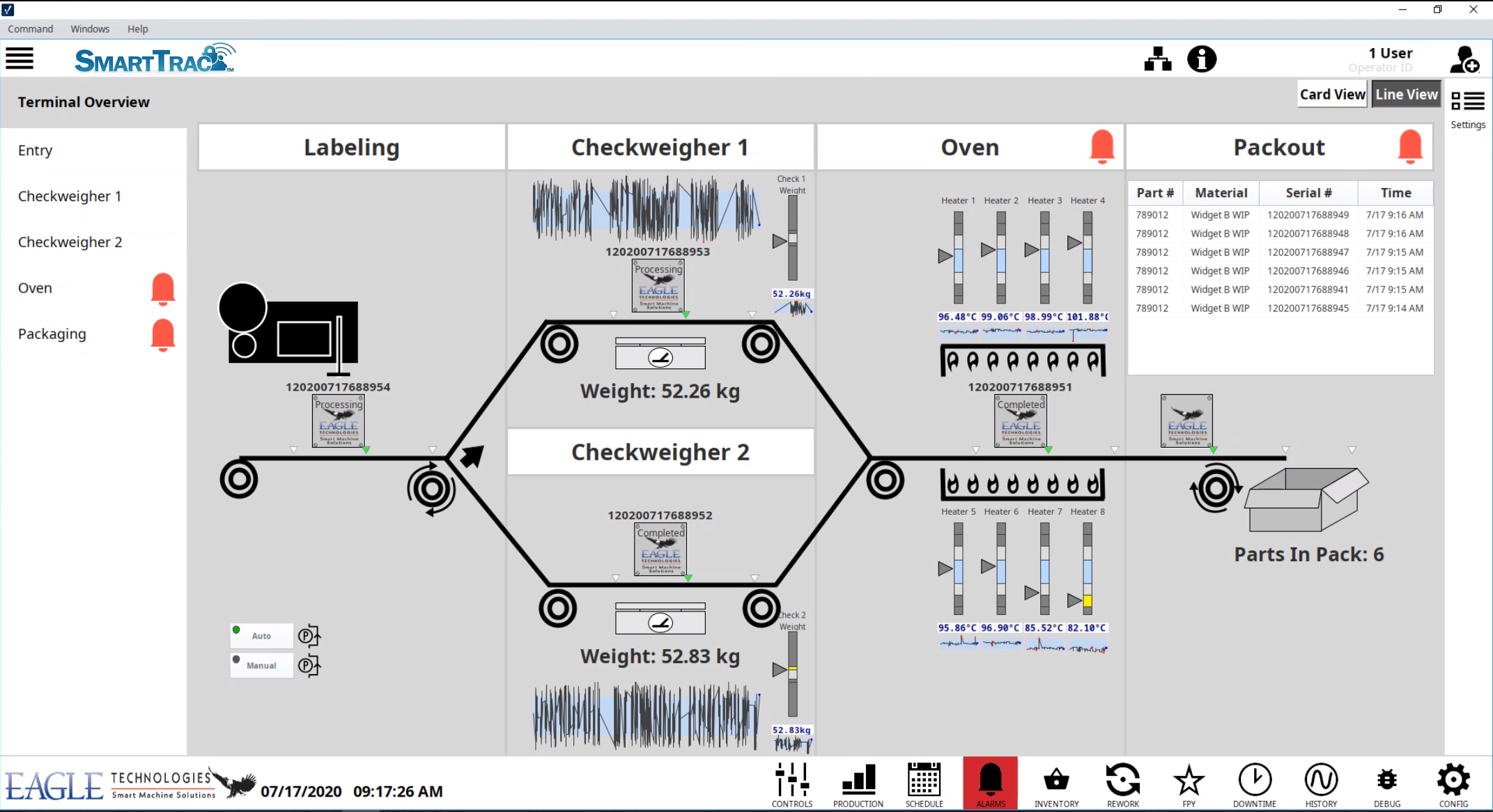

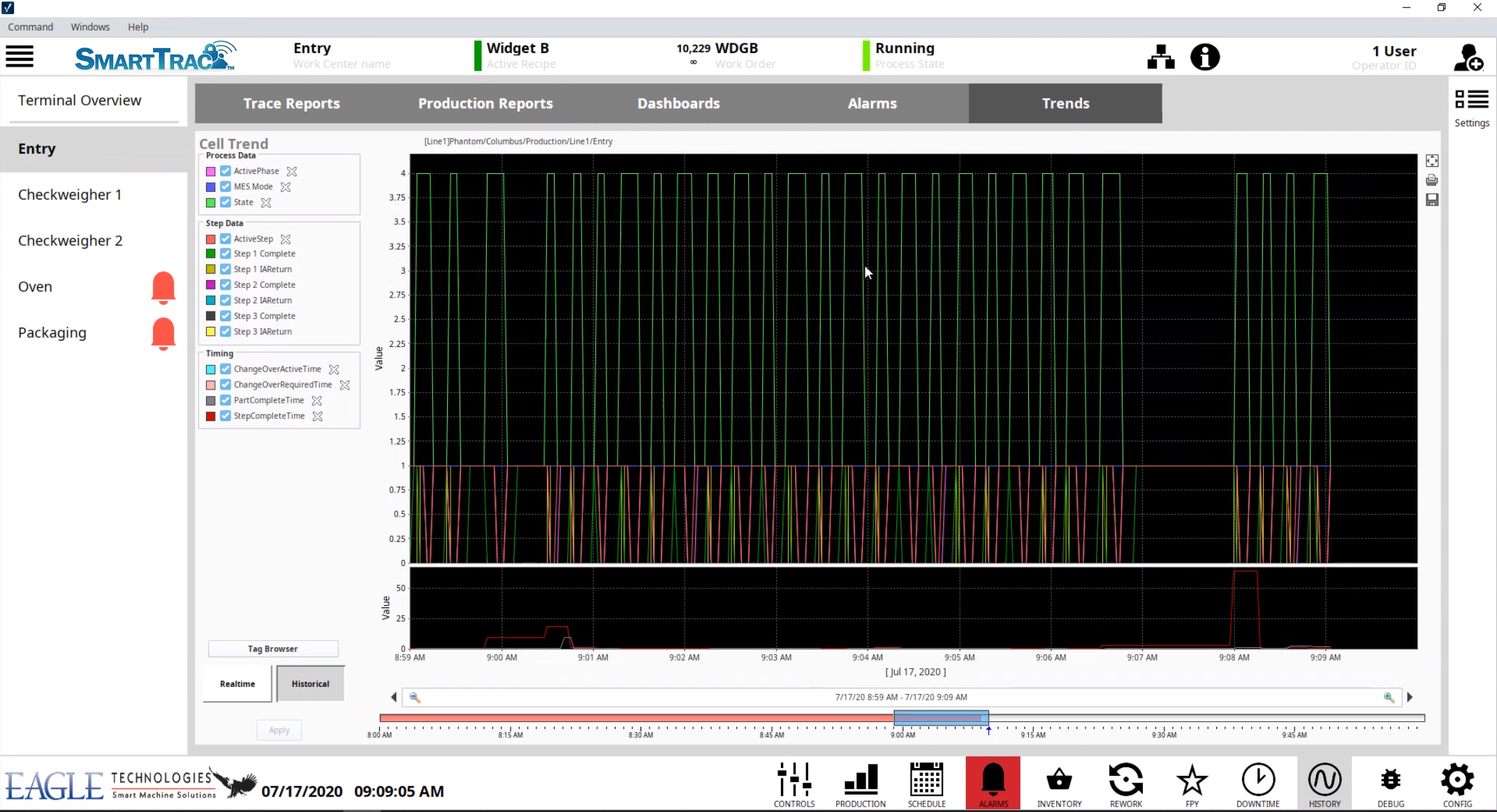

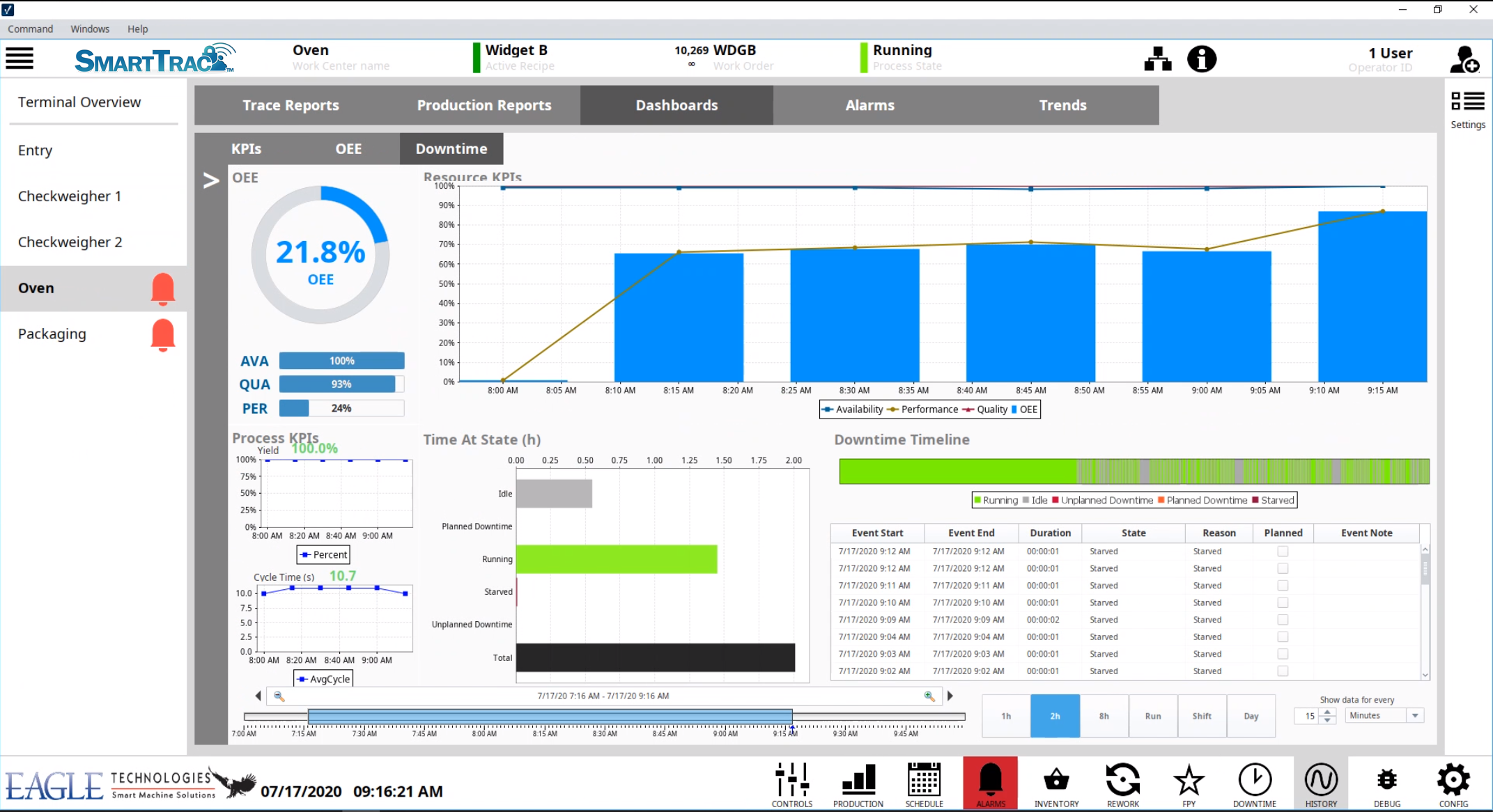

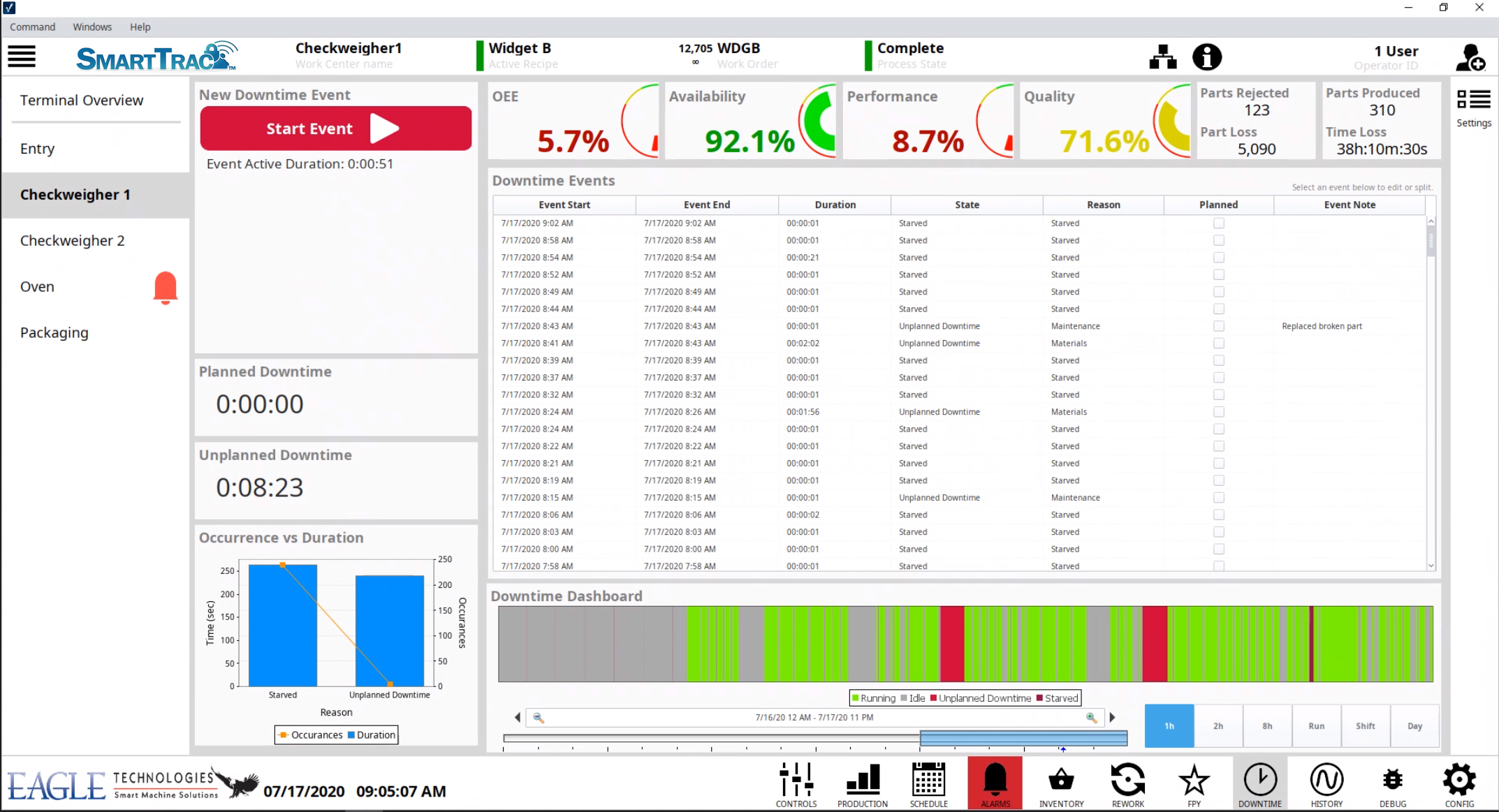

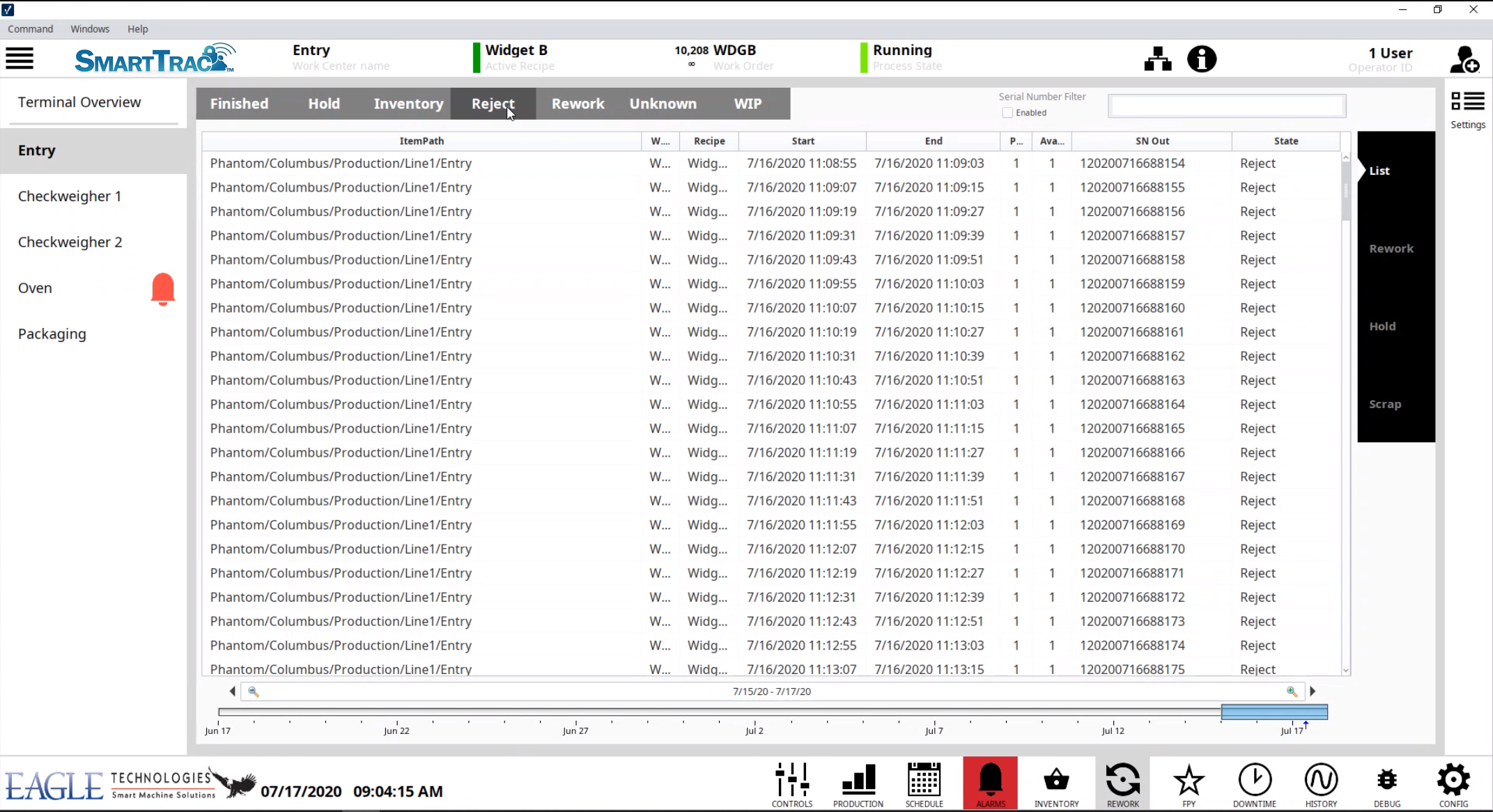

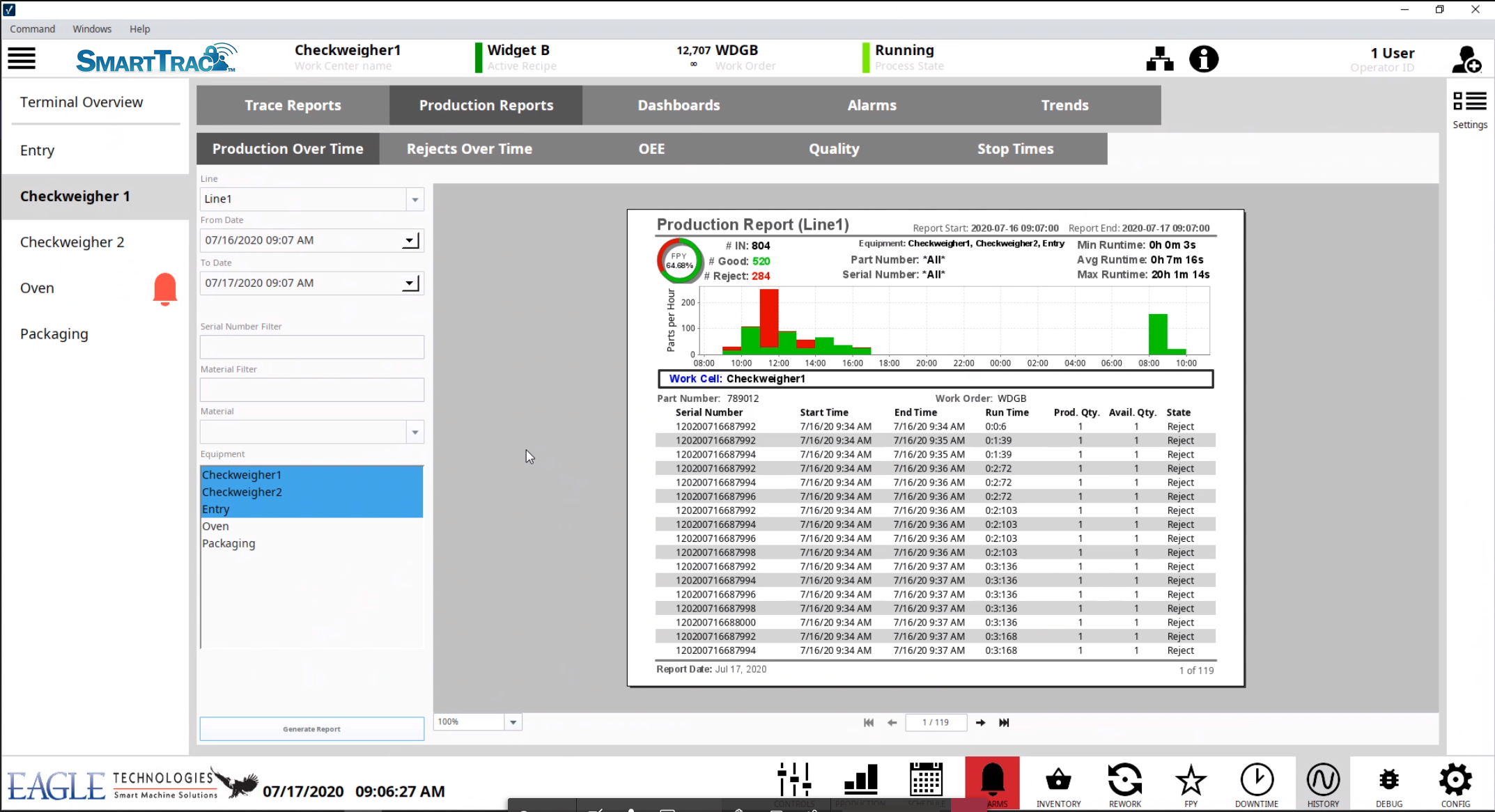

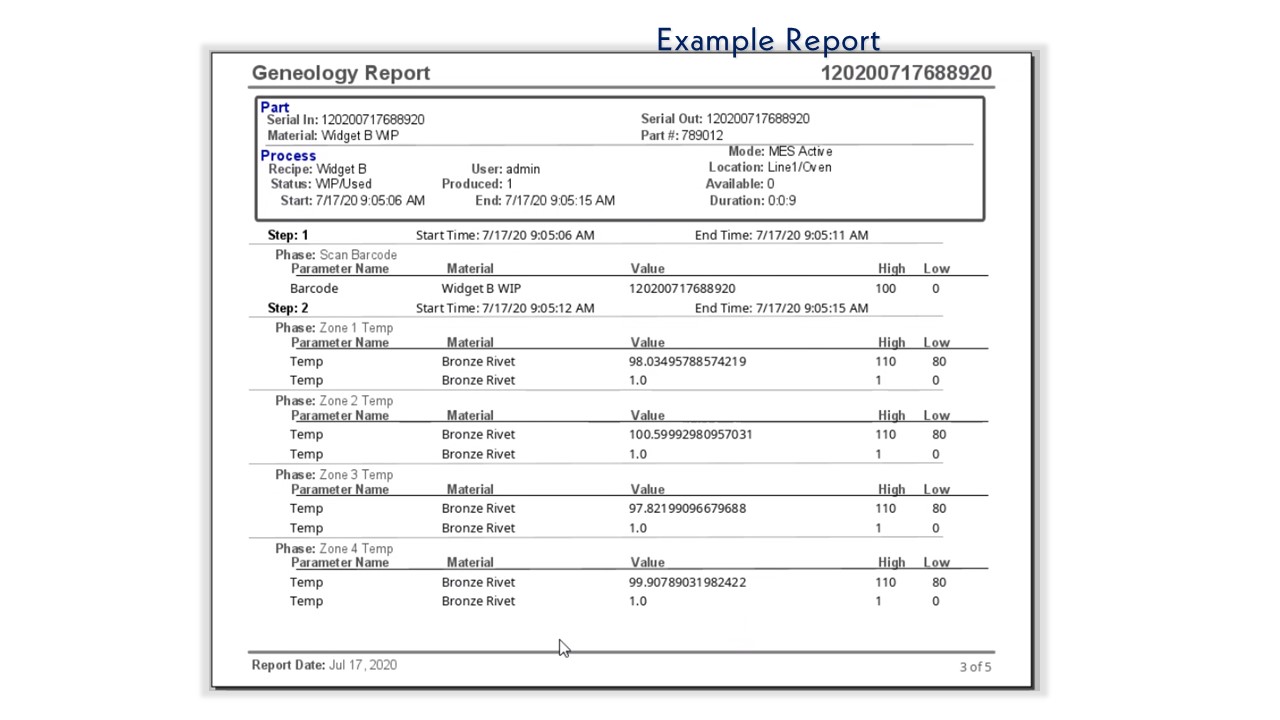

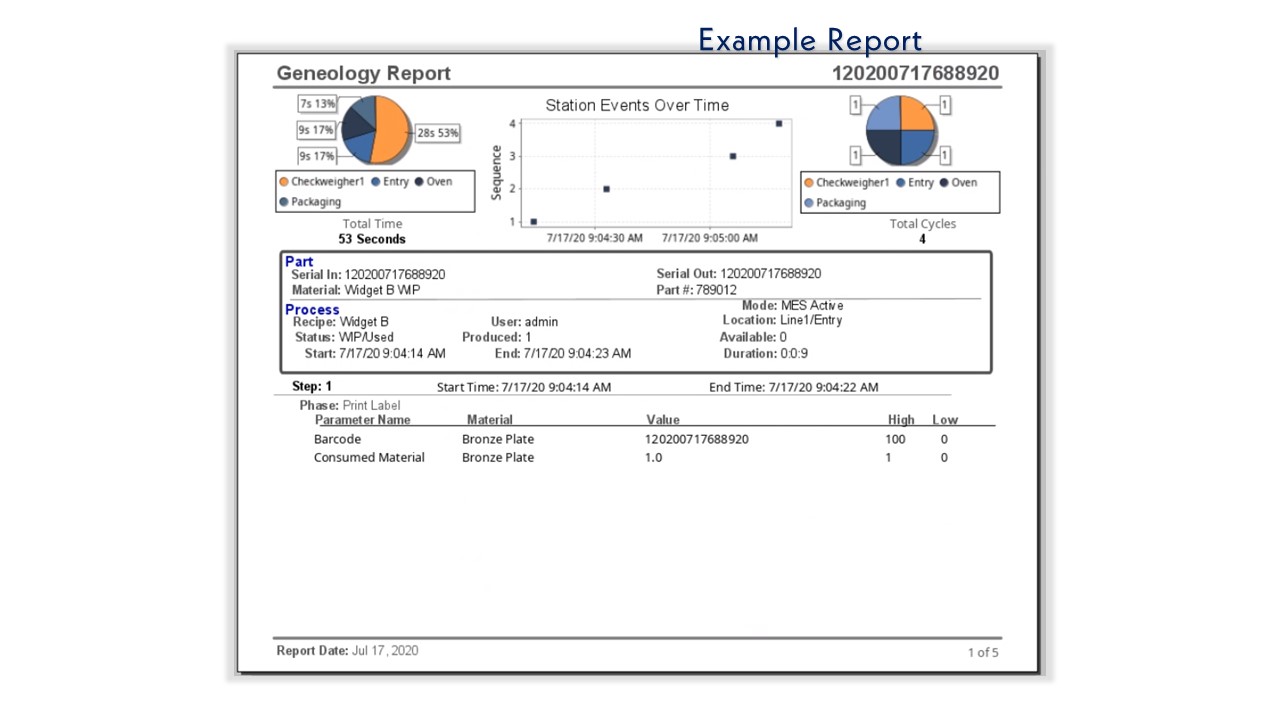

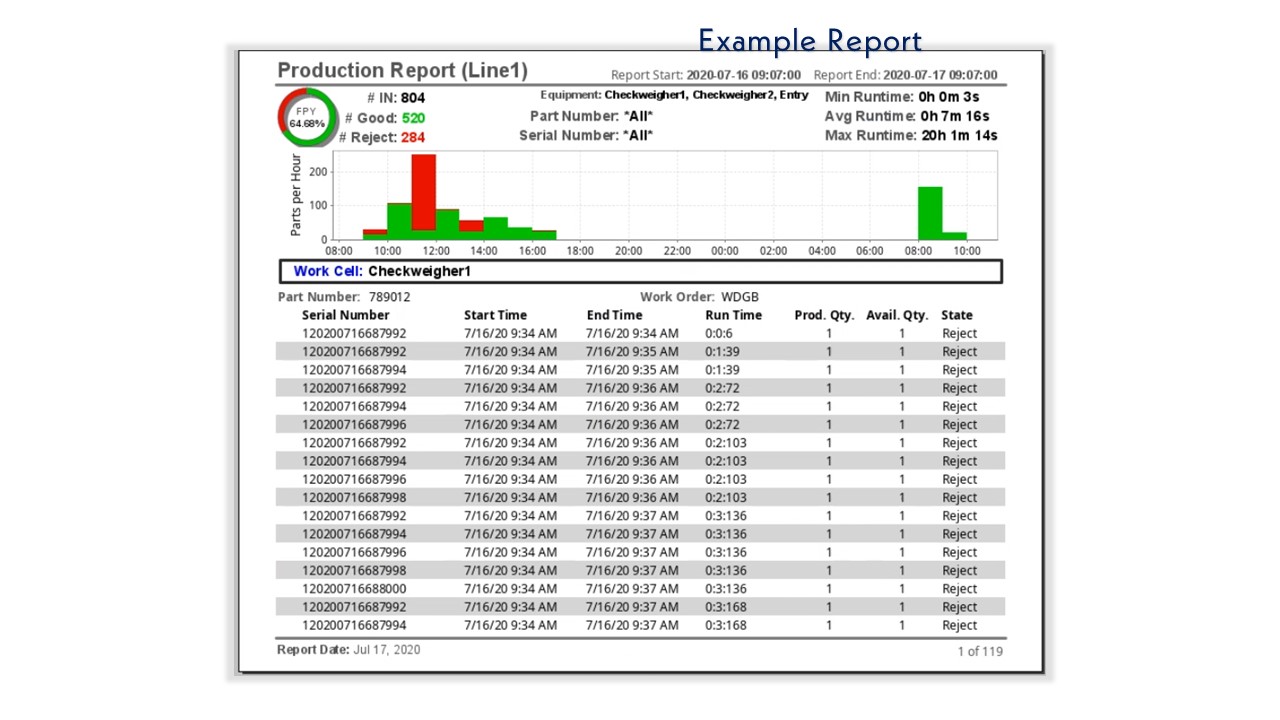

Reports and dashboards

Click on the images below to scroll through the various dashboard and report examples.

- Workorder Schedule Dashboard

- Workorder Production Dashboard

- Workorder Monitoring Dashboard

- Monitoring, Line View

- Monitoring, Station Overview

- Station Control/Monitoring

- Station Control/Monitoring

- Operator Instruction Example

- Process Control Dashboard

- Process Control Dashboard

- Analytics, KPI DashboardDashboard

- Analytics, First Pass Yield Dashboard

- Analytics, Downtime Dashboard

- Station OEE Dashboard

- Traceability Dashboard

- Traceability Report

- Example Report

- Example Report

- Example Report

INTEGRATION

Integration is simple with SmartTrac IoT Suite. We use common communication protocols, API’s, and commercially available software packages, which allow for easy integration and without extensive custom programming or custom drivers. Built on industry-recognized software platforms such as Inductive Automations Ignition and PTC’s Vuforia, the SmartTrac IoT Suite is easily supported by most customers, with training available from Eagle, IA, and PTC.

The SmartTrac IoT Suite can be installed on Eagle provided hardware or supplied on a Virtual Machine to be placed on equipment in the customer’s server room. Data gathered by SmartTrac can be stored on customer-provided hardware, Eagle provided hardware, or in the cloud.

Analytics of the processed data streams are provided in standard reports and dashboards. Customized reports and dashboards created by Eagle engineers based on individual customer requirements are also available. With proper training, additional reports and dashboards are easy to create.