Over the course of the 20th century, factory automation transformed production lines to become ever more efficient. Now, modern robotic automation solutions are set to revolutionize the industry once more, providing high-speed solutions to previously difficult assembly challenges.

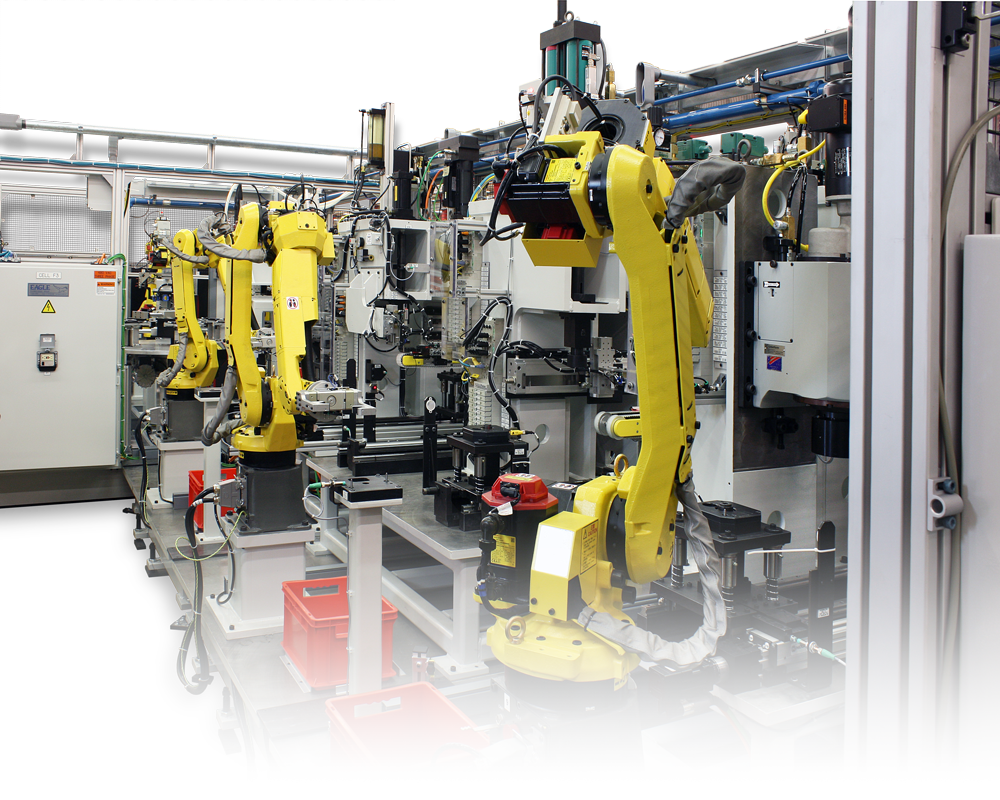

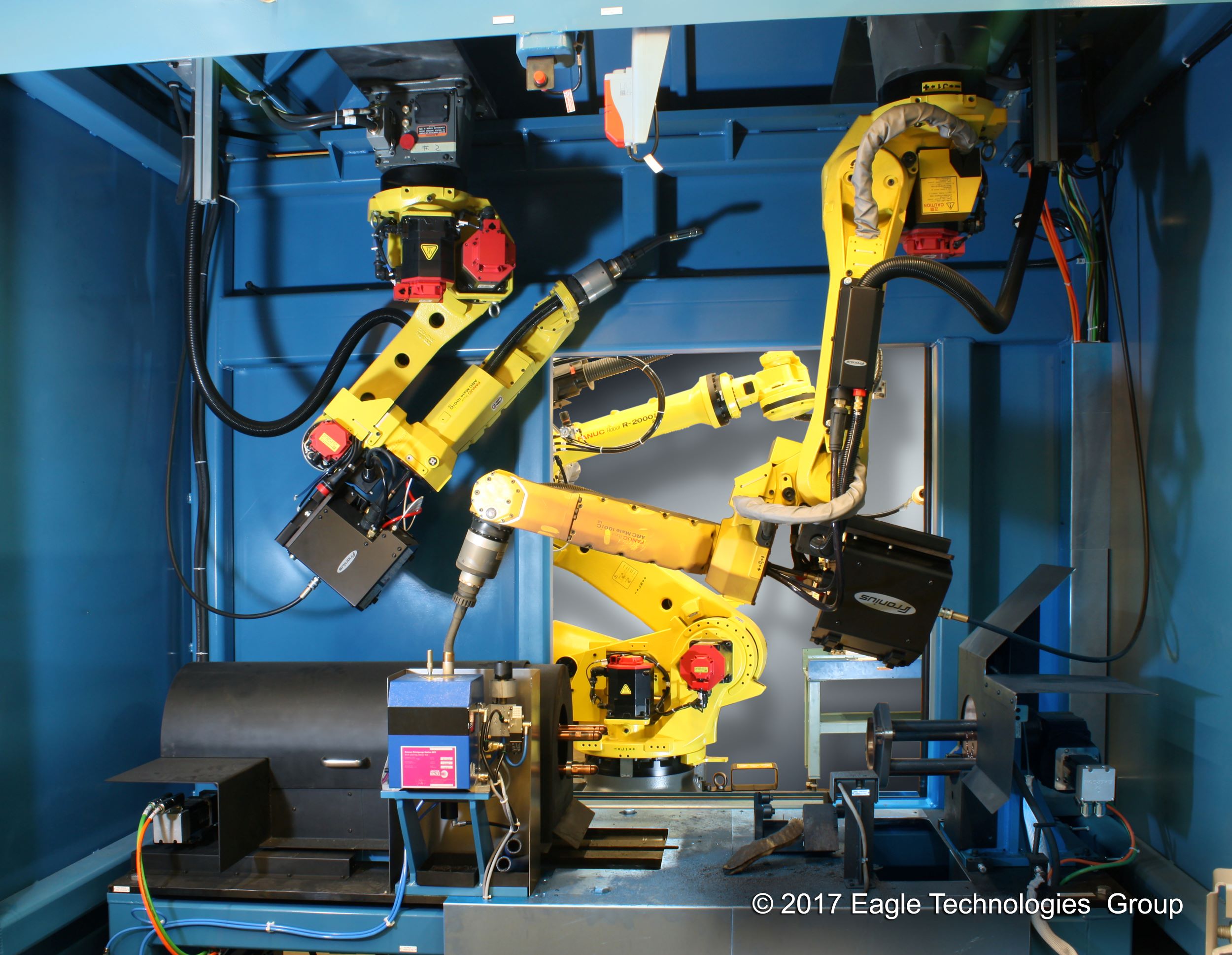

As experts in factory automation, we at Eagle Technologies have always challenged ourselves to be at the forefront of our field. When it comes to robotic automation, this has meant developing partnerships with high-end robotics suppliers within our industry, as well as investing in advanced technology to support our development process. As a result, we are at the top of our industry when it comes to incorporating advanced robotics into automated assemblies.

-

Eagle’s Expertise:

90M Annual Sales

50 Years of Automated Systems

1,000 Installations Worldwide

280K Square Feet of Facilities

EAGLE’S ROBOTIC AUTOMATION CAPABILITIES INCLUDE:

- Robots from FANUC, Yaskawa Motoman, Denso, ABB, KUKA, and more

- 6-axis pick and place technology

- Multiple EOAT with high payload

- High-speed precision walking beam

- Torque and depth control and monitoring

- Vision-guided robotic material handling and part location

- Chip collection and removal

- Tool breakage sensors

- Vision inspection

Automated battery assembly using the latest smart manufacturing techniques.

EV battery production needs to scale to keep up with the market demand for electric and hybrid vehicles. Fortunately, automation capabilities in the past few years have risen to meet this challenge, offering new techniques to both assemble and test EV batteries.

These capabilities include high-speed robotics with 6-axes of mobility that can lift, orient, and place components, adhesive dispensing technology that is accurate to the nanometer, and ultrasonic wire bonding capabilities that can fuse materials at the atomic level.

Automated testing on stand-alone machines or in-process.

Quality and consistency is essential to EV battery production, which is why we incorporate product testing directly into our assembly processes. These verification steps can also be handled independently as stand-along procedures, either for spot-testing or to add new verification methods to an already existing assembly process.

Our visioning technology means we can also conduct scan inspections without adding another step to the process, and our barcode systems mean you can track units as they progress through your system and identify them for product tracing purposes.

“I want to thank the Eagle team for a job well done under extreme (COVID-19) circumstances. It is a pleasure to work with people who take real ownership for their work and I hope I have an opportunity to work with them in the future.”

—FORTUNE 500 – TOP 15 AUTOMOTIVE PART MANUFACTURER

Full integration of robotics and automated assembly technologies.

Many industries have already partly automated, relying on traditional fixed-in-place assemblies for high volume manufacturing applications, and turning to human operators for tasks that have historically been resistant to automation. But with advanced robotics shifting the parameters on what is or isn’t possible to automate, it’s time factories rethought their assemblies.

Fortunately, robots can be incorporated within a more traditional assembly, either with the assembly that already exists, or when used alongside other high-volume manufacturing methods. At Eagle, we use automation simulations to understand how each assembly component interacts with each other, so that the assembly we design uses the most effective technology for each task.

Vision-guided technology for inspection and quality control.

The greater mobility and agility of robotic solutions combined with advanced vision technology means they can perform tasks previously unfeasible for traditional automation—such as inspecting crops for ripeness, or working alongside human operators on large aerospace assemblies. Vision inspection systems also reduce the human error that is inevitable when a worker grows weary or loses focus.

We at Eagle place a high priority on the excellence of our product, and focus on quality applies to the assemblies we design for our customers as well. We can help you use visioning technology to gather data about your quality control processes so that you can identify problems early and nip any production issues in the bud before they cause trouble downstream.

Contact Eagle Technologies to learn more about our robotic automation solutions.

If you are looking for a robotic automation partner for your company, Eagle has your back. We are stationed in locations around the globe, from the heart of American manufacturing in the Midwest, to the innovation center in California, and a new installation and support center in China. We also have global manufacturing partners stationed in Ireland and Mexico.

Contact us today to learn more about our capabilities, or come see for yourself by arranging a visit at one of our manufacturing locations.

Lets Talk.

Contact us and we’ll be happy to help!